According to the situation, PRG uses the most efficient gunning technique:

-

Dry concrete gunning

The concrete passes under pressure through a pipe to the area to be repaired. At the nozzle, the specialist adapts the quantity of water required for the optimum installation depending on the type of surface where it is applied.

-

Wet concrete installation (shotcreting)

PRG specialises in this technique that consists in mixing the concrete with water before sending it through the pipes. Shotcreting allows a correct product/water mix and consequently reduces product rebound. Nevertheless, the technique needs several conditions to ensure installation quality.

-

Mix both techniques

According to the project, it is possible to mix both techniques of concrete installation. From our experience, we advise the customer on the most ssuitable choice.

Choice of the most suitable solution

The choice of the refractory material for repair of furnaces, regenerators or closing of joints depends on individual furnace conditions and of the refractory to be repaired.To avoid any problems on site and to increase the lifetime of your installation, PRG always offers the solution most appropriate to your environment and your problem, in terms of :

- type of concrete used

- quality and performance

- technique of implementation (dry way or shotcrete)

- final application

- time of execution

- Rebound percentage…

For example, the glass industry where work is carried out at very high temperature, the dryinstallation technique is preferred, in order to avoid concrete setting directly in the pipes. Currently, we are still developing other techniques.

The 5 steps of an efficient repair with PRG

-

Cleaning or demolition of damaged linings

A quality preparation of the surface is very important to ensure the success of a repair. Dust and loose material must absolutely be removed to guarantee a good implementation.

-

Sandblasting

Before gunning, the repair area is cleaned and moistened by blowing either sand under pressure or just air or water from the nozzle.

-

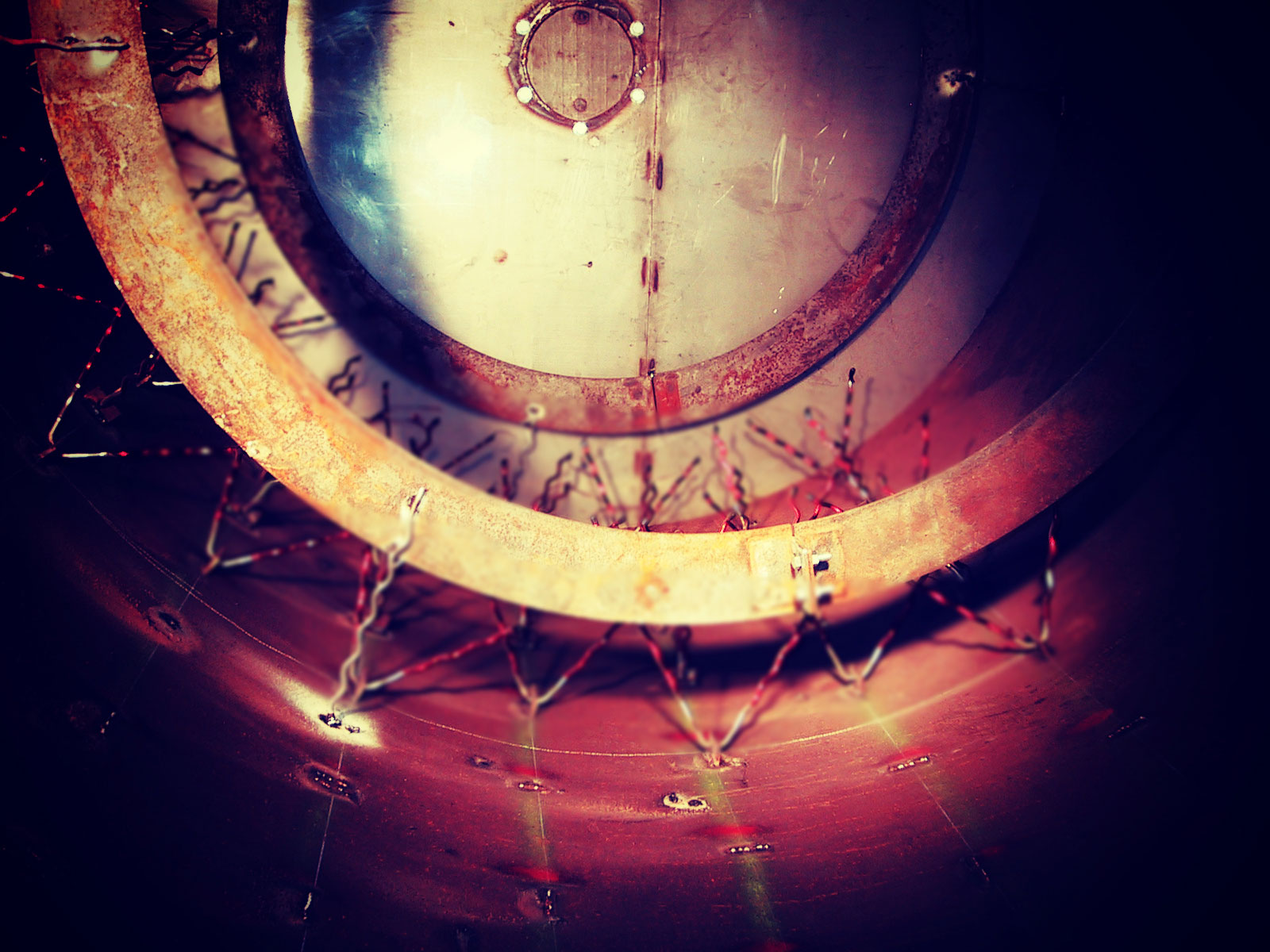

Welding

Welding of mesh/anchors (in steel/ stainless steel) to fix the concrete.

-

Anticorrosion painting

Anticorrosion painting of the surface to be treated and protect the metallic coating from chemical attacks (only in the case of gas cleaning).

-

Installation of concrete by dry method or shotcreting

During this process, the water volume and the pressure are carefully checked to moisten the mixture in order to avoid drying prior to impact.